Products

Here you can find a selection of our automatic lathes, woodturning lathes and drum sanding/coating machines.

automatic lathes

The STEINERT MINIMAT 25 combines modern design principles and ease of operation with exceptional economy in the smallest possible space. The fully automatic machine is designed for the highly productive production of small parts up to 24 mm in diameter. It has a magazine feed of prefabricated round bars up to 600 mm in length. Collets in the spindle head ensure maximum accuracy.

TECHNICAL DATA

turning length: 60 mm

turning diameter: 2 mm - 24 mm

Drilling depth: up to 60 mm

Magazine loading: prefabricated round bars from 6 mm - 25 mm D

quantity output: up to 1400 turned parts per hour

tool holder: dovetail holder

drive motor: 1,5 KW, 380 V 3 Ph, 50 Hz

Electrics: safety electrics according to VDE motor protection IP 54

Compressed air: 55 l/min at 6 bar input pressure

Dimensions: L 2150, W 850, H 1500

Weight: 425 Kg

Basic equipment: The machine is equipped with 2 counter-rotating rotary supports (one swiveling), a cut-off support, a drilling support and a length stop system.

Accessories at extra charge: Infinitely variable speed control, feed tongs, steel holder7

Der Drehvollautomat STEINERT MINIMAT 45 schließt den Kreis für einen Durchmesserbereich bis 44 mm. Der Vollautomat besitzt die Merkmale unseres Programms: moderne Konstruktionsprinzipien, hoher Bedienkomfort, außergewöhnliche Wirtschaftlichkeit, geringer Flächenbedarf.

Der Automat besitzt eine Magazinbeschickung für vorgefertigte Rundstäbe bis 600 mm Länge.

TECHNISCHE DATEN

Drehlänge: 100 mm

Drehdurchmesser: max. 44 mm

Bohrtiefe: 80 mm

Magazinbeschickung: vorgefertigte Rundsätze von 10 bis 45 mm D

Mengenleistung: bis 1200 Drehteilen pro Stunde

Werkzeughalterung: Schwalbenschwanzaufnahme

Antriebsmotor: 2,2 KW, 380 V 3 Ph, 50 Hz

Elektrik: Sicherheitselektrik nach VDE Motorschutz IP 54

Druckluft: 65 l/min bei 6 bar, maximal 100l/min bei 6 bar

Maße: L 2600, B 1200, H 1450

Gewicht: 650 Kg

Grundausstattung des Automaten: 2 gegenläufige Drehsupporte, beide anhebbar, 1 Abstechsupport,

Drehzahlregelung: 5-stufig über Bediengerät vorwählbar

WEMA Minimat 65 CNC - CNC-controlled automatic wood turning lathe

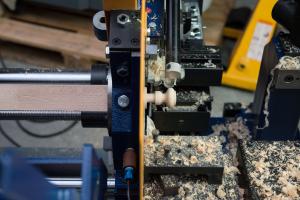

The WEMA Minimat 65 CNC is a fully automatic lathe for mass production of turned wood parts up to a diameter of 65 mm.

The machine is equipped with two CNC controlled turning supports. In addition, it has a CNC-controlled wood material delivery, pneumatically controlled drilling support and pneumatically controlled parting support.

The two turning supports can be used with either form steels (profile blades) or copying turning tools. Thereby it is possible to work traditionally with two opposite profile blades. It is also possible to use a combination of turning tools and profile blades or to use two, optionally three different copying turning tools. This flexibility allows a high variety of workpiece geometries. The assembly of the turning supports directly behind the steady rest guarantees excellent turning quality.

The WEMA Minimat 65 CNC is characterized by high efficiency in large series and also smaller quantities. Even individual pieces or test parts are efficient and fast to produce.

The supports are programmed via a CAD / CAM system. As blanks square or round bars can be used, which are supplied via a magazine.

TECHNICAL SPECIFICATIONS

- Turning length: 3 mm - 120 mm with profile blades, optionally up to 450 mm with copying turning tools

- Turning diameter: 3 mm - 65 mm

- Drilling depth: up to 100 mm

- Drill holder: Morse Taper 3 (optional MT 2)

- Blank length: 340 mm - 800 mm

- Spindle speed: electronic controllable in 3 ranges from 900 to 5600 rpm

- Drive motor: 3 kW (4 hp)

- Blank servo motor: 0.4 kW (0,5 hp)

- Turning supports: 0.2 kW (0,25 hp)

- Electrics: Safety electronics VDE motor protection IP protection classes IP 54

- Voltage connection 400 V / 230 V, 3L / N / PE

- Total power requirement: maximum 4.2 KW

- Dust extraction: 3 x 100 mm for rotary supports, drills and roughing tool

- Compressed air: connection 5 to 6 bar

- Compressed air consumption: maximum 90 l/min, average 30 - 50 l/min

- Dimensions: L 2450, B 1200, H 1320

- Weight: 620 Kg

Our hapfo CHALLENGE machines are fully automatic CNC wood turning machines for the production of large series with the highest demands on accuracy and highly complex parts. They offer all the technical advantages that characterize a high-performance fully automatic CNC wood lathe. The hapfo CHALLENGE can turn, mill, flute, drill and grind and is ideally suited for large series and parts ready for painting.

We offer the machine in two versions and with a wide range of optional additional functions.

The two basic machines have the following parameters:

"hapfo CHALLENGE-5000"

Distance between centers: 1,600 mm

Copy length: 1,300 mm

Copy diameter: up to 300 mm

"hapfo CHALLENGE-7000"

Distance between centers: 1,750 mm

Copy length: 1,450 mm

Copy diameter: up to 400 mm

Special features of the hapfo CHALLENGE:

Headstock and machine bed made of high quality gray cast iron

Backlash-free mounting of the hollow spindle (suitable for vacuum connection) with thread M 45 and inner cone MK 4.

Storage of the support on linear guides with servo motor drive

Heavy gray cast iron tailstock with quick release eccentric and MT3 cone

thin parts possible thanks to the leading steady rest, when using the ring steady rest with pre-cutting steel, planing of the raw material is not necessary

Optional turning tool swivel device for continuous cutting even with balls and grooves

Optional belt sanding unit with PC control for pointed and flat sanding on round profiles. Turning and grinding in one operation

Simple and practice-oriented operation with special turning functions

Less training required thanks to the use of simple 2D CAD software

Production of several parts in "bar mode" possible

Fluting can be produced in any number of pitches and gradients with the milling unit, which can be swiveled and height-adjusted in several directions.

Drive:

7.5 kW three-phase motor with frequency converter regulated and controllable via the program.

Spindle speed range from 0 to 3200 rpm.

Magazine:

The newly developed magazine combines the experiences from previous generations with some interesting and extremely useful innovations. It is self-centering and can clamp both rectangular and round raw material. By using the rollers in the gripper, the system can also be used as a program-controlled support steady rest, which enables a considerable reduction in production times, especially with slim parts. Thanks to the internal gripper, warped raw material can also be used more efficiently. It can be operated completely from the front. The finished parts are ejected to the front. The minimum dimension of the cross-sections is 20 mm. Automatic operation is possible up to 100 mm. The grippers can also be used as an insertion aid up to a cross-section of 130 mm. The workpiece length can be continuously adjusted between 140 mm and 1300 mm.

Software and programming:

Standard software MegaCAD LT for creating the contour

Data import and export in all common formats

All additional parameters are entered and saved in the machine software.

All menus are graphically supported and marked with symbols. All important information such as speed, feed, positions of the axes or the current program progress is displayed at any time. The magazine can also be easily operated manually.

Handwheel for operating mode manual / automatic:

A handwheel with display to show the selected operating mode is optionally available. With this, all axes can be positioned quickly and precisely in manual mode. In automatic mode, START / PAUSE / STOP as well as speed and feed can be continuously controlled at any time.

The solution for individual requirements. These hapfo CNC wood lathes are modern further developments of the tried and tested hydraulic hapfo copying machines.

The machines are available in two basic versions:

hapfo 5000-CNC:

Centre width: 1,600 mm

Copying length: 1,480 mm

Centre height: 250 mm

Drive: 2.2 kW motor

hapfo 7000-CNC:

Center width: 1,800 mm, 2,900 mm or 3,700 mm

Copy length: 1,620 mm, 2,720 mm or 3,520 mm

Center height: 300 mm

Drive: 4 kW motor

Hapfo CNC lathes are suitable for the production of larger quantities under the highest demands on accuracy. The high-precision, high-performance machines in heavy grey cast iron design and first-class workmanship from German production have exceptional advantages. Turning support and longitudinal slide run on hardened and ground, low-maintenance ball track guides. The turning steel is very close to the travelling steady rests, which guarantees low-vibration turning of the workpiece profile. Steady rests and accessories can be retrofitted at any time. Production of small parts is possible in "bar mode". Fluting can be produced in any pitch and gradient. For this purpose, a simple and robust top milling unit is available in a horizontal position and fixed at centre height, or alternatively a unit which can be swivelled in several directions and adjusted in height for any conceivable task.

New and simplified software enables practice-oriented operation with special turning functions. Low training requirements due to the use of simple 2D CAD software and common PC hardware.

Technical features:

- Headstock and machine bed made of high-quality grey cast iron with milled and ground bed guide

- backlash-free bearing of the hollow spindle (suitable for vacuum connection)

- 5000-CNC: thread M33 / inner cone MK 3

- 7000-CNC: thread M45 / inner cone MK 4

- Bearing of the support on linear guides with servo motor drive

- Tailstock in heavy grey cast iron design with eccentric quick clamping and cone MK3

- thin parts possible due to leading steady rest

- when using the ring steady rest with pre-cutting steel, planing of the raw material is not necessary

- optional turning steel swivel device for continuous cutting even with balls and grooves

- with 3-axis version controlled servo motor with speed range from 0 to 4000 rpm

Dimensions and weight:

5000-CNC:

L:2600 mm, W:700 mm, H:1.230 mm

weight: approx. 750 kg depending on version

7000-CNC:

L:3.250 / 4.350 / 5.150 mm, W:1.260 mm, H:1.300 mm

weight: approx. 1.000 kg to 1.600 kg depending on version

woodturning lathes

Hand lathes of the “steinert® piccolo” series are made of grey cast iron and thus correspond in their basic construction to solid professional lathes. As table lathes, they are only smaller than the standing machines; however, their areas of application are unlimited. The professional uses it in his workshop or for mobile face turning and the amateur has a fully-fledged, high-quality machine at his disposal for which there are a large number of accessories and interesting expansion components. High quality turning and model making work can be carried out with this machine.

- Centre height: 150mm (180mm for a surcharge)

- Distance between centers: 350mm (1000mm with extended bench bed)

- Motor: 400v, 0.75 KW 50 Hz

- Mains connection: 230v, 50 Hz)

- Speeds in rpm: variable in 3 areas of 145 to 2900 (with 50 Hz mains connection)

- Headstock / spindle: grey cast iron with hollow spindle with spindle thread M33 / DIN 800 and MT2

- Spindle bearings: maintenance-free storage

- Tailstock: Grey cast iron with inner quill taper MT2, quill stroke with handwheel 60 mm

- Toolrest: 160mm, shaft 25mm

- Weight in kg: 58

- LxWxH in mm: 1000x200x320

- Centre height: 250mm

- Distance between centres: 1100mm

- Motor: 2,2 KW, 400v; 50 Hz (other motors with different power and voltage can be installed for a surcharge)

- Mains connection: 230v, 50 Hz

- Speeds in rpm: variable in 3 ranges from 70 to 3600

- Headstock / spindle: grey cast iron with hollow spindle (bore 12 mm) with spindle thread M33 / DIN 800 and MK 2 inner cone, rotatable with displaceable centering plate

- Spindle bearing: maintenance-free triple bearing with preloaded shoulder bearings and counter-pressure bearing at the end of the spindle for hard stop work. NOTE: The counter-pressure bearing closes the hollow spindle

- Tailstock: grey cast iron with inner quill taper MT 2, quill stroke with handwheel 120mm

- Control panel: magnetic control panel

- Hand rest rail: 425mm, shaft 40mm

- Weight in kg: 350

- LxWxH in mm: 1950/600/1200

Video: Eurosymposion der Drechsler in Oberwolfach (Schwarzwald), Vorführungen auf der Drechselbank steinert® gamma

Vorführer: Martin Adomat mit Alabaster drechseln, Holger Graf drechselt eine Halbkugeldose, Helmut Jäger drechselt eine römische Dose aus Bein (Rinderknochen).

Die DVD mit allen Drechsel-Vorführungen in voller Länge erhalten Sie im DrechslerMagazin-Lesershop unter www.drechslermagazin.net

The new Steinert® VGM300 hand lathe is an essential for our three heavy machines VB36, Gamma and Maximo.

The wishes and experiences of turners who are looking for particularly solid and long-lasting turning technology made in Germany, have been incorporated into the development of this machine.

A massive, torsion-resistant cast bench bed serves as the base frame, which has already proven itself in numerous machines from the Gamma series and is also used in our large CNC lathes. The machine's electronics are located in the left foot, protected from dust. The right foot can be filled with sand at the designated parking space in order to further improve stability. The tailstock and palm rest also come from the Gamma range.

For the headstock, we rely on the proven design of our high-end Maximo machine. The wide bearing spacing and a stabilising sleeve between the bearings can easily withstand high rotational forces. Additional screw connections of the headstock and bench bed guarantee an extraordinary overall stability of the drive unit. Nevertheless, the headstock can be rotated 360 ° and moved along the entire bed.

The VGM300 has a bayonet connection for holding chucks, as is also used on the VB36 head lathe. This guarantees that the extremely robust overall construction continues until the tool engages the workpiece.

Technical data (subject to technical changes) :

- Centre height: 300mm

- Distance between centres: 1100mm (larger centre widths optionally possible)

- Headstock: cast iron, 360 ° rotatable with centering plates, movable, additional screw connection on bench bed

- Spindle: reinforced double hollow spindle with 18mm bore, double pre-tensioned angular contact ball bearings on the working side, ball bearings on the rear, additional back bearing

- Mounting: VB36 bayonet flange Ø 100mm, inner cone MK3

- Power transmission: 3-stage poly-V belt drive with 12 grooves, width 28mm

- Tailstock: cast iron, quill stroke 120mm, inner cone MT3

- Hand rest rail: cast iron, width 425mm, shaft 40mm

- Motor: 2.2 kW, 400v; 50 Hz

- Mains connection: 400v, 50 Hz

- Control: infinitely variable in 3 ranges from 70 to 3600rpm, right-left rotation, switchable start-up and braking times

- Control panel: mobile control unit with holding magnets

- Weight: 400kg

- L x W x H: 1950 x 600 x 1250mm

VGM - das Beste aus drei Welten! VB36 + Gamma + Maximo

The "VB36 Master Bowlturner Lathe" - that's the correct English name - has rightly earned the status of a cult machine in recent years. The unlimited access to the workpiece makes the lathe an ideal tool for making large bowls or vessels. Plain bearings ensure extremely smooth running. The weight of 265kg also defies heavy workpieces.

When designing this machine, the aim was to achieve maximum stability, precision and safety for all areas of manual turning. Machining large workpieces usually causes forces that are difficult to calculate. Mastering these forces is only possible with a heavy grey cast iron machine with generous overall dimensions and the corresponding components. Coupled with a powerful drive and modern electronics, the designers have succeeded in creating a new reference class with the "steinert® - maximo".

Technical specifications:

- Centre height 335mm

- Distance between centres 1500mm, 3850 or 6200mm for an extra charge

- Spindle mount bayonet flange 125mm, internal mount MT 3

- Strongly dimensioned double hollow spindle with 18mm bore with precision angular contact ball bearing and additional back bearing

- Drive 2.2kW, 400volts (3HP), 50Hz (stronger motors are possible)

- Stepless electronic speed control with three switchable starting and braking times. Control via a mobile control unit, which is connected to the frequency converter via a spiral cable

- Right-left rotation of the spindle with switch on the left machine stand

- Power transmission via 3-stage poly-V belt drive with high-performance belt type 12 PJ 836 (belt width 28mm)

- Speeds: 70-540 / 240-2100 / 620-4650rpm

- Tailstock quill: quill stroke 160mm, internal mount MK 3, large handwheel, chrome-plated, measuring scale on request

- Tool support rail 425mm, shaft 40mm

- Weight 540kg in the standard version, 660kg with external turning device

- Dimensions: L = 2550mm, W = 670mm, H = 1250mm

Designed for the professional user, the PERFORMER 400-FU presents all technical advantages which

are characteristic for an efficient wood turning lathe. With a centre height of 402mm, and the swiveling

headstock there are all possibilities to realise extraordinary artwork.

Characteristics:

• Headstock can be swiveled and moved all over the bed

• headstock made of cast iron

• pretensioned bearing of the hollow shaft free from backlash (suitable for connection with vacuum device) with thrust M33 and inner cone MT 3.

• Centering related to DIN 800 with 34mm.

• Handwheel

• Tool rest (275 mm) with quick-clamping

• Tailstock MT3, made of cast iron with quick clamping

Technical specifications:

• Centre distance: app. 1000mm

• Centre height: 402mm

• Infinitively variable spindle speed with frequency controller

• Motor 2.2kW, 400V; 50Hz

• Power supply 230V or 400V

• Spindle speed from 10 to 4000rpm

• Two pulley drive system, 10 to 1000 rpm and 100 to 4000 rpm

• Left and right direction

• Electronic cabinet in machine leg integrated and protected against dust

• Lockable main switch, 2 sockets 230V for e.g. light and sanding machine, switched ON/OFF with main switch

• Weight 340kg, can be increased up to >400kg by filling sand in the tubes

• L x W x H: 1770x775x1280

drum sanding and coating machines

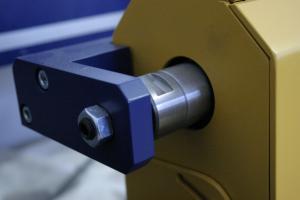

The steinert TRU is a tumbling barrel machine for grinding, polishing and deburring small parts of different materials. The machine is equipped with a slow running geared motor and a variable speed control. Drum bodies from 400 to 700 mm diameter can be fitted to the steinert TRU with an easy to use bayonet fitting. The mobile stand and a swivelling drum mounting allow comfortable operation. The machine is characterized by its compact and solid construction, is low-maintenance and has an long lifetime. We also offer barrels in different dimensions.

TECHNICAL SPECIFICATIONS

Speed: electrically variable from 3 to 37 rpm

Barrel dimensions: Ø 400 to 700 mm (key width), length up to 400 mm

Barrel fill weight: maximum 30 kg

Motor: 0.37 kW

Power supply: 230 V, 50 Hz

Safety electronics according to VDE

Protection class IP 54

No exhaustion connection

Dimensions: L 750, B 550, H 1420 mm

Weight: 80 kg

Technical changes reserved.

Universal-Polier- und Schleiftrommelmaschine mit Ständer,

Preis inklusive einem Trommelflansch aus Stahl zum Befestigung der Trommel, aber ohne Trommel.

geeignet für Trommelkörper mit 400 bis 600 mm Durchmesser (bei größeren Trommelkörpern sind zusätzliche Vorrichtungen gegen Aufpreis möglich)

Ständerausführung mit stufenloser Drehzahlregelung, Motor 0,37 kW, 400 Volt 50 Hz,

Absaugung von Lackdämpfen und Staub über Hohlwelle

Kraftübertragung von Getriebemotor zur Trommelwelle über Keilriemen

Maschine zum Schleifen, Färben und Lackieren mit nichtbrennbaren Stoffen

Anmerkung: Die oben angegebene Trommelmaschine verfügt zwar über einen geschützten Motor, die Ansteuerung (Schaltelement) ist aber nicht Explosions-geschützt. Solche geschützten Ansteuerungen sind sehr teuer. Deshalb empfehlen wir, die Schaltelemente außerhalb des explosionsgefährdeten Raumes installieren zu lassen oder Wasserlacke zum Trommeln zu verwenden.

Weitere Trommelmaschinen (Größen, Ausführungen, Doppeltrommeln etc.) bieten wir auf Anfrage gern individuell nach Ihren Bedürfnissen an.

STEINERT Trommelmaschine Typ EN 17 – Doppeltrommel für zwei Trommelkörper zum Schleifen und Färben und Lackieren mit nichtbrennbaren Materialien.

Hohlwelle für Absauganschluss zum Absaugen von Lackdämpfen und/oder Stäuben.

Kraftübertragung von einem Getriebemotor zur Trommelwelle mit Keilriemen.

Drehzahlregelung über Frequenzumrichter 10 bis 30 U/min.

Standardmaschine ohne Trommelkörper mit Getriebemotor 0,37 kW, 400 Volt

- für Trommelkörper bis zum Durchmesser von ca. 800 mm (nicht im Preis und Lieferumfang enthalten)

- mit zwei Trommelflanschen (im Lieferumfang enthalten)

- ohne Ex-Schutz (nicht für brennbare und entflammbare Oberflächenmaterialien!)

Es sind verschieden große Trommelkörper (achteckig aus Schichtpressholz) und passende Aufnahmeflansche lieferbar. Preis je nach Größe auf Anfrage.

Doppeltrommelmaschine mit zwei übereinanderliegenden, getrennt steuerbaren Trommelkörpern.

2 Motoren 0,75 kW

stufenlose Drehzahlregelung 10 - 30 U/min

digital einstellbarer Timer

elektronische Sicherheits Doppeltür

230 V Netzanschluss

ohne Absauganschluss

vorrangig zum Entgraten, Schleifen und Polieren geeignet

Abmessung Maschine: T:810 x B:1600 x H:1950 mm

Abmessung Trommelkörper: Länge: 1150 mm; Schlüsselweite: 600 mm; 2 Kammern